Groove diameter d 053 x d groove radius x 2 053 x 14mm 74mm x 2 74mm 148mm 4. Please contact us to get your winch drum hoist drum and crane drum now.

Pitch diameter p 5.

. 1 T ranslation of design requirements into specif. Lebus also adjusted the level winders which is a mechani-cal rope guide system and changed the gear ratio to match the number of pitches on the Lebus groove. When the wire rope need to wind many layers the LBS groove can fix the crossover point of the upper rope and the lower rope through crossed groove which could control the crossover point and make it finished in the crossed groove.

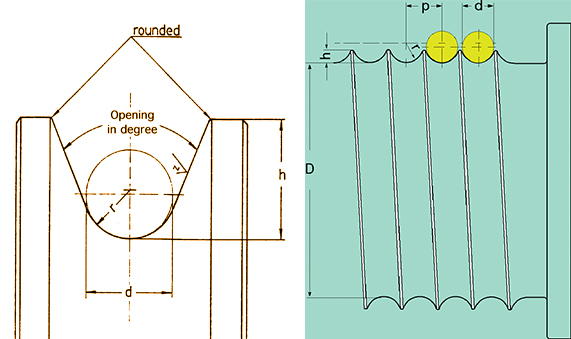

Opening angles below 35 must be avoided. Not generally suitable for pitch design since this may involve. Available space for the design and dimensioning of the drums.

1 over the actual wire rope diameter. Given are applicable to grooves in sheaves and drums. Deep Mining Winch With High Effency.

Yet by Federal standards a 14-inch rope may have a diameter as large as 265 inches. Groove depth 2065 x groove radius h 0374 x d 2065 x 74mm 0374 x 148 15281mm 55352mm 6. Minimum 0375x d for helical grooved.

Winch loads are light and infrequent. 2065 x groove radii Drum Pitch for SINGLE layer maximum. Groove radius r 3.

Customized Non-standard wire rope multi-layer w. Diameter of drum Ddrum ratio between 20 to 25 x drope 20 x 14 280 mm 2. If a rope of this size were to be operated on a drum with a 250 inch pitch crowding would occur and the rope would be forced out of the groove.

Applications with deflection angles of more than 15 use 60 opening. 15 x d or d x 2. Ordinary duty working environment.

Rope drum design is the main objective in this paper. As an example a grooved drum made for 14-inch rope may have a pitch of 250 inches. The drum V-groove design which is not consistent with the recommendations of the Wire Rope Users Manual maybe acceptable for light loads.

Due to this the constant development of calculation methods for a design appropriate to the loads is of great interest to crane and winch manufacturers especially as the design criteria of the present norms seem arguable. 218 x groove radii Drum groove depth. Recommended Sheave and Drum Contours.

3 the selection of materials in engineering design involves. Lebus Rope Groove Drum Hydraulic Crane Winch Wi. Further the dimensions do not apply to traction-type elevators.

The company uses advanced design systems and the use of advanced ISO9001 2000 international quality management system management. 053 to 0535x d for new rope Groove radii maximum. It is composed of two parallel grooves and two crossed grooves in each circle of the winch drum.

Leave your requirement below and custom drum design solution will be offered for free. 055 to 056x d Sheave Groove depth. Traction winch system sheaves absorb high line pull loads by allowing the cable to work in a formed groove at the required minimum bend diameter.

Minimum 053 to 0535 x d Maximum 055 x d Recommended. For normal applications use 35 to 45 opening. According to Ashby et al.

LBS Sleeve Drum Enginee Machine Suitable To Wokover Rig Logging Electric Device. Problem definition and calculation methods. Winches Lebus simply welded new split sleeves on to the drum together with false flanges to make the length of the drum match the new grooving and compensation plates.

86 150 3617 7583. Wire rope sling lefLBS groove design for winch or marine winch drum. Marine Windlass Boat Winch Grooved Drum Carbon Steel Integral Type.

Drums Plain Smooth. 1The advantages of multilayer winding. High quality Multi Functional Hydraulic Tower Crane Winch LEBS Groove Drums from China Chinas leading Multi Functional Tower Crane Winch product with strict quality control Hydraulic Tower Crane Winch factories producing high quality Hydraulic Tower Crane Winch products.

However heavy tensile loads will result in severe pinching of the wire rope and galling of the drum groove especially with a lubricant-starved 304 stainless wire rope. Marine Windlass Boat Winch Grooved Drum Carbon Steel Integral Type. Can be get to 10000M.

High quality Lebus 200m Wire Rope Drum Grooved Winch Drum For Marine Winch from China Chinas leading Lebus Grooved Wire Rope Drum product with strict quality control 200m Wire Rope Drum factories producing high quality Lebus grooved winch drum products. Wire Rope Drum With LBS Groove Sleeve Bolted For Crane Towing Winch. High Efficient Tower Crane Engineering Wire Rope Winch Drum Single Drum.

Start your homemade winch project by scrounging up a discarded manual shift car or truck transmission available from your friendly local scrap-iron dealer for. This single-layer effect is significant when compared with high line pull conditions in a conventional drum winch in which cable works on itself as a result of multiple layer wraps. The valving to your winch design should work such that air or oil to your air or hydraulic motor should be provided BEFORE air or oil reaches and releases the band or disc brakes otherwise when hoisting or pulling up a slope you can have an overrunning load in which - should your brakes be released BEFORE your motor inlet ports are FULLY pressurized -.

Circumstance drum-and sheave-groove tolerances should conform. Drum Pitch for SINGLE layer minimum. 05 ton small chain fall hoist 35 ton heavy electric chain fall hoist.

Acoording to the drum length. Lebus sleeve is a more efficient approach.

Introduction Drawing Calculation For Winch Design

Crane Rope Drum For Sturdy Crane Spare Parts Of Dqcranes

Model Gh15 Features And Benefits Equal Speed Forward And Reverse Operation High Speed Reverese Available On Some Units Mult The Unit Compact Design Speed

Pulleys As Simple Machines Pulley Simple Machines Pully System

Model Pd17 Features And Benefits Free Fall Available On Some Units Groove Drum To Help Prevent Spooling Issues Available On Some Clutch Gear Multi Clutch

0 comments

Post a Comment